Ports of Auckland is one of New Zealand’s largest container ports and primary port by import volume. At present POAL handles ten trains per day with the capacity of loading/ unloading 492 TEUS in a 24 hour period. To enhance operational efficiency at rail side, POAL decided to implement Camco’s Rail OCR Solution. The system is fully operational since November 2018, and allows for automated identification and inventory of containers and railcars.

DROPPING MANUAL DATA ENTRY WITH 95%

Ports of Auckland Rail planner Jackie Dickinson elaborates: “The Rail OCR system is very user friendly and effective. It has reduced manual data entry to the bare minimum (data entry dropped with 95%) and it eliminates human error. In our experience, the system is very thorough when reading container numbers and ISO codes. Errors in pre-advised lists relating to container size or type are noticed and can be followed up on easily. For example, we’ve had containers pre-advised as 20’ when they were 40’, and containers pre-advised as GENL when they’re covered in hazardous placards.”

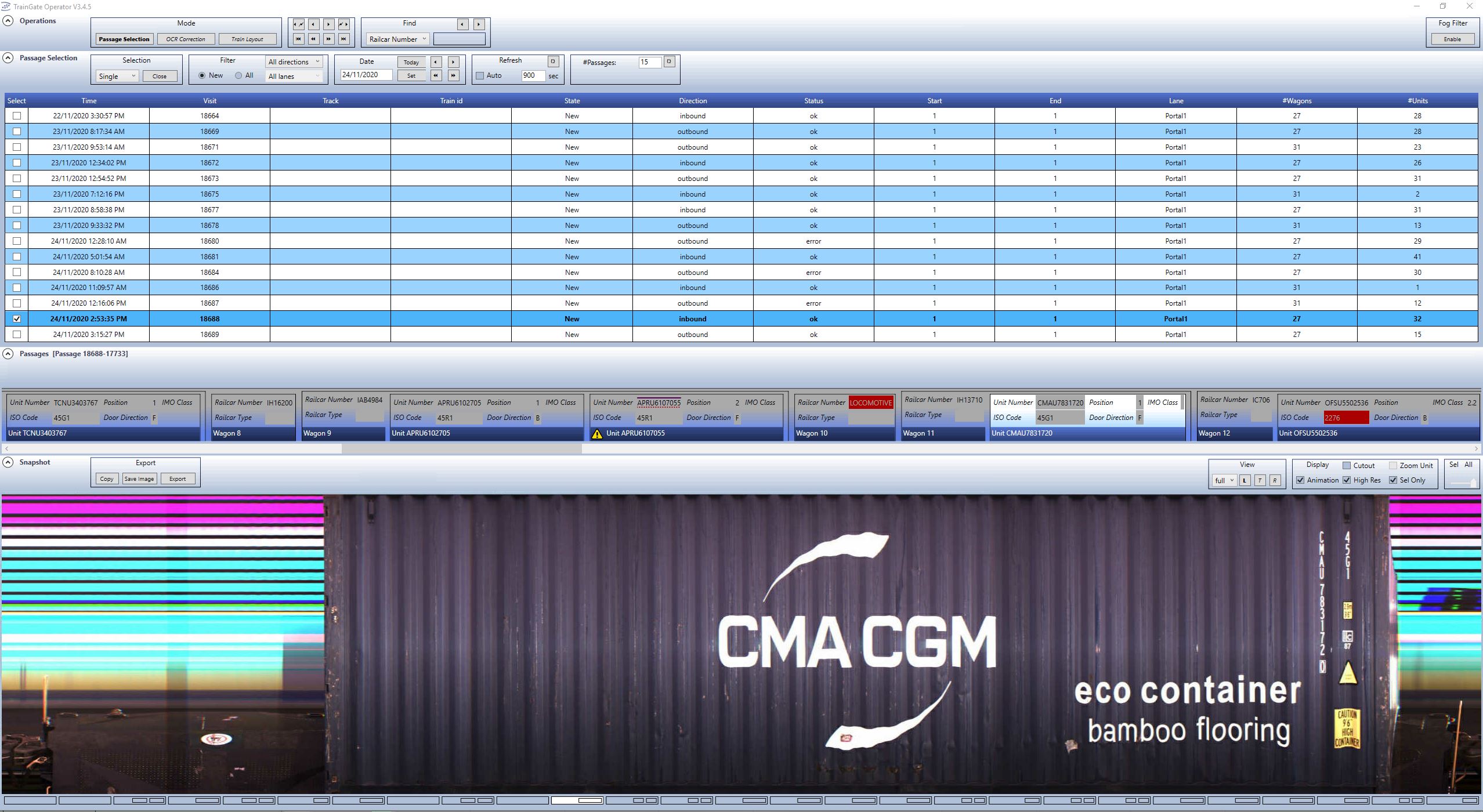

TRAIN GATE OPERATOR FOR DATA VALIDATION AND CONDITION CHECK

The system comes with a Train Gate Operator application, where operators perform post-processing tasks. This application allows operators to visually inspect the condition of each container and railcar, and verify, correct and validate the OCR processed data. When the collected information is complete and correct, the processed data is sent to the TOS for further processing.

The Ports of Auckland Train Gate Operator is a comprehensive application capturing all Rail OCR data including an exception handling tool and crisp pictures for condition recording.

“We are really enjoying using this system and are learning new things all the time about what it can do,” continues Jackie. “It has made the Rail Planners job so much easier than having to run around the yard trying to discover if an export arrived or not. It’s so much easier to use the application to look for the

container.”

Aera scans (above) and line-scans (below) providing sharp pictures for exception handling and condition recording