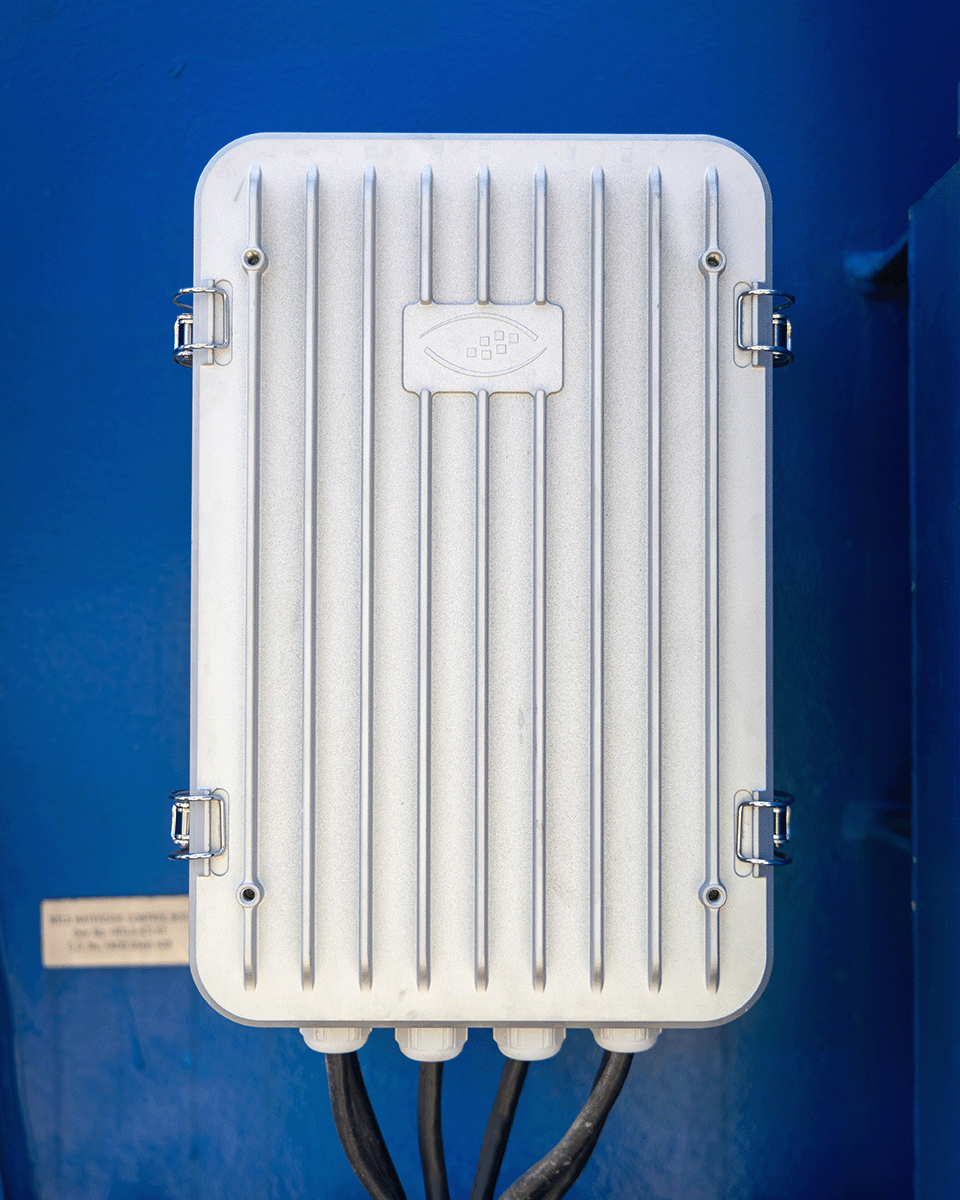

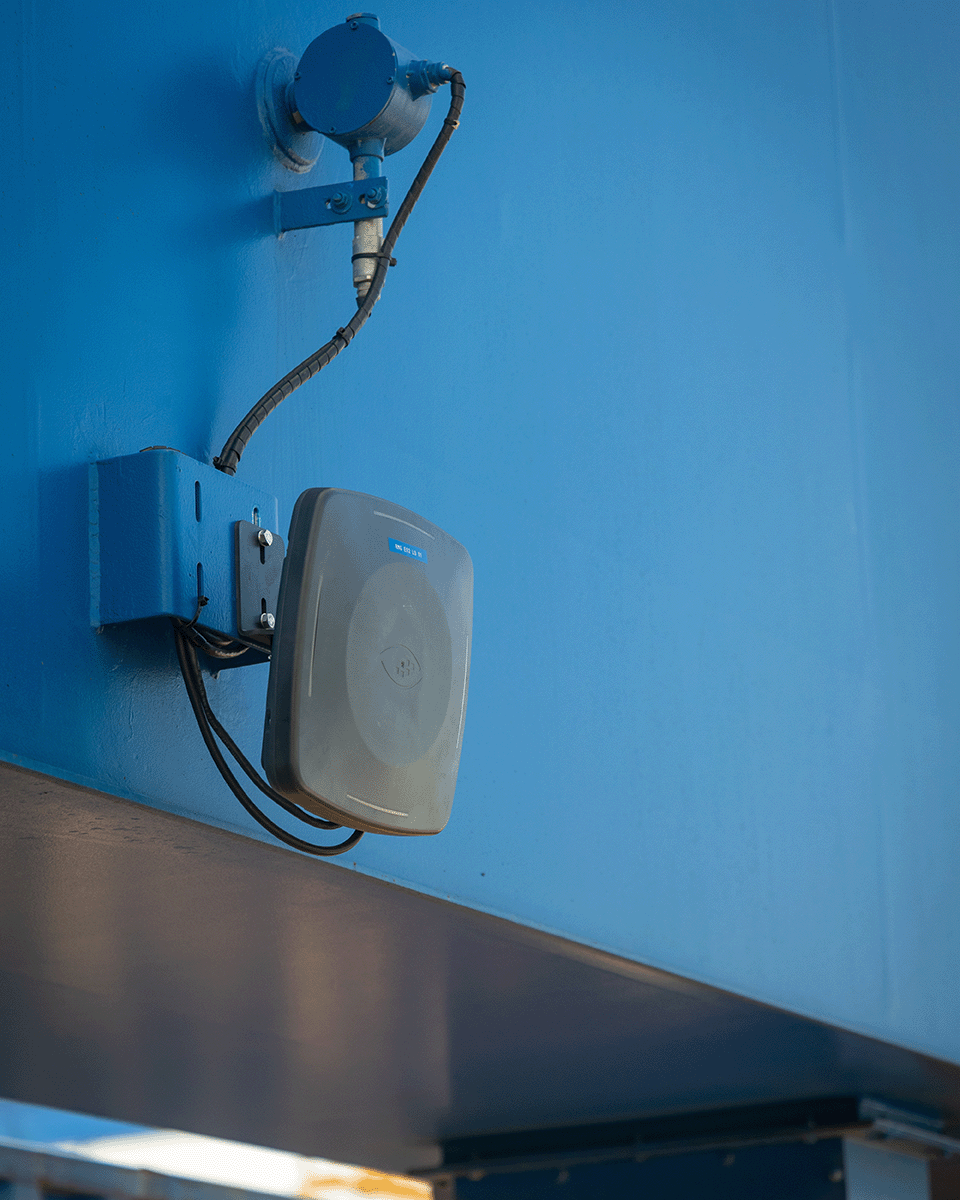

TriTech RFID Reader

Camco designed the TriTech RFID reader specifically for container yard automation, integrating the latest RFID chips to extend the read range up to 12 meters. This advanced reader combines an integrated antenna, radar, and camera for enhanced performance. The radar detects vehicle presence, preventing erroneous tag readings caused by reflections. Meanwhile, the camera allows remote visual monitoring of the RFID reading zone. For greater coverage, users can connect additional external antennas.

Additionally, the TriTech RFID reader ensures seamless compatibility with industry standards like EPC GEN2 and RAIN. It also meets FCC, CE, and country-specific conformity certifications.

Camco deploys these RFID readers across key terminal locations, including OCR portals, gate lanes, yard entry points, yard block entries, and RTG and RMG cranes.

MLT/UWB Solution

Camco’s GNSS solution covers 90% of the yard’s surface, but the area under STS cranes presents a unique challenge. Multipath effects, signal blockage from vessels or cranes, and atmospheric conditions often disrupt GNSS data, making it unreliable.

As a backup, INS (Inertial Navigation Systems) provides accurate positioning for moving vehicles. However, once stationary, INS begins to drift, causing inaccuracies over time.

To solve this issue, Camco developed a Micro Location Technology (MLT) solution using Ultra-Wideband (UWB) devices. Six UWB antennas, or anchors, are installed on the STS crane, while two UWB antennas are mounted on the straddle carrier or ITV. By transmitting RF pulses between the six STS antennas and the two vehicle antennas, the system calculates the vehicle’s location and identification with centimeter-level accuracy.

GNSS Receiver

Camco’s GNSS receiver is the backbone of our RTLS solution, installed on all moving vehicles, including straddle carriers, ITVs, RTGs, RMGs, empty handlers, and reach stackers.

Designed for efficiency, this compact, fully integrated device houses two GNSS receivers, two embedded antennas, a processor, and a 470MHz radio receiver—all in one unit. With just a single POE Ethernet connection, installation is simple and hassle-free.

To enhance performance, the integrated radio receives RTCM messages directly from the GNSS base station, providing a more reliable and efficient alternative to Wi-Fi transmission.

Telematics

RTLS becomes even more powerful when combined with telematics data from the vehicle. While GNSS pinpoints a truck’s location along its route, telematics adds valuable insights, such as whether the truck is parked and turned off or idling with a driver inside. It also transmits critical engine and tire data.

To enable this integration, all CHE’s come equipped with PLCs. Camco connects the MLT controller to the vehicle’s PLC via Profibus or CAN bus, allowing telematics data to flow seamlessly into the BRIDGE and Camco’s RT Digital Twin.

Acting as the vehicle’s central processor, the MLT controller unifies GNSS, UWB, PLC, VMT, and the Alignment LED bar into a single, streamlined system.

Part of the automation chain

All our terminal truck location technology it is part of our THE BRIDGE platform.

Within this ecosystem, it adds precise truck positioning to enable smoother handovers and better coordination across ship-to-shore and yard operations.