A perfect view

Identifying containers at height, in motion and under varying light conditions is challenging — especially in high-throughput terminals.

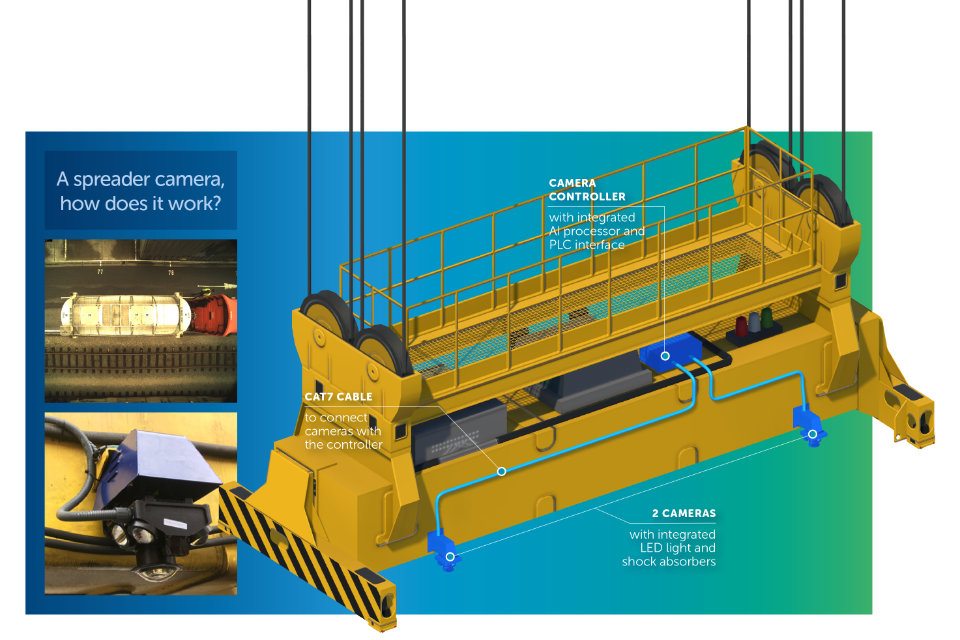

A spreader camera provides clarity exactly where it is usually lacking.

It enables:

- Direct visual confirmation beneath the spreader

- Accurate container ID through integrated recognition

- Automatic damage inspection of the roof and corner castings

- Fewer handling errors during pick-up and set-down

- Improved safety for personnel and equipment

The result is faster work cycles, fewer interruptions and more reliable operations.

Engineered for extreme conditions

A spreader operates in one of the harshest environments in the terminal.

Theoretically shock loads up to 100G, continuous vibration, wind, salt exposure, humidity and rapid temperature shifts — it all happens daily. Spreader systems also sit on the low end of a crane’s reliability tree; they are among the most failure-prone pieces of lifting equipment, with MTBF values typically ranging from 100 to 800 hours depending on age and maintenance.

In developing our spreader camera solution, we had to cope with this harsh environment.

That is why spreader cameras are:

- Equipped with shock absorbers built for heavy impact

- Fitted with integrated LED lighting for consistent visibility, day and night

- Housed in sealed, industrial-grade enclosures

In short: they are built to perform reliably in years of continuous operation.

Seamless integration with crane control

The two cameras connect via a thin cable to the camera controller mounted on the spreader headblock.

This controller processes the image stream and interfaces with the operator station, PLC or terminal network. It requires a hardwired connection to the E-house — either via ethernet or spare wires within the trolley cable chain.

Depending on the setup, the video feed can be:

- Shown live to the crane operator

- Linked to OCR processing

- Used to support automated handling logic

The system is suitable for:

- STS cranes

- RTG / RMG cranes

- Reach stackers and other container-handling equipment

Part of the automation chain

The spreader camera is not a standalone feature — it is supported by our BRIDGE platform.

It becomes a building block in real-time container recognition, automated damage inspection and seamless handover workflows across ship-to-shore and yard operations.

This technology doesn’t just provide visibility.

It provides confidence — and confidence is what drives automation forward.