Key features

- Full crane OCR/OFR: container ID, ISO code, seal presence, IMDG label presence/classification, container door direction

- Sharp images in any condition and at any container traveling speed

- One-fits-all solution for various container configurations: single, tandem, quad 20′, 30′, 40′, 45

- Front- and back-reach operations

- Easily accessible maintenance position

- No constrained spreader path

- Argus Automated Damage Detection enabled

- Optional washing station for automated and scheduled BoxCatcher cover cleaning

The first moving camera system for STS cranes

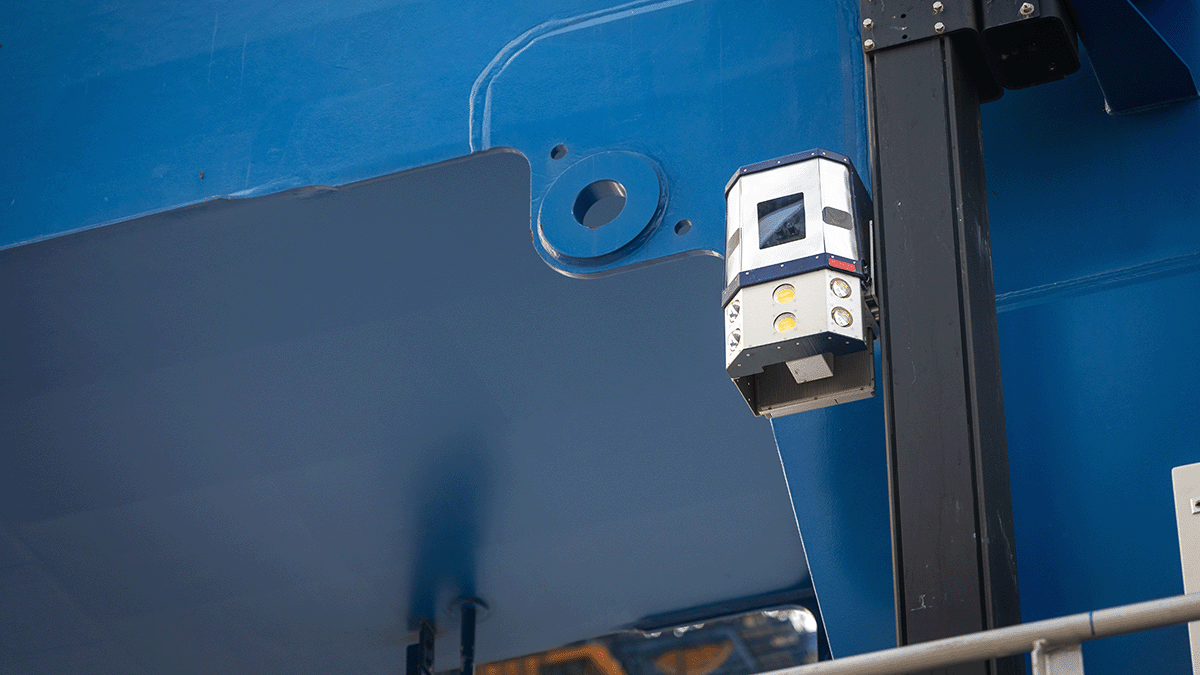

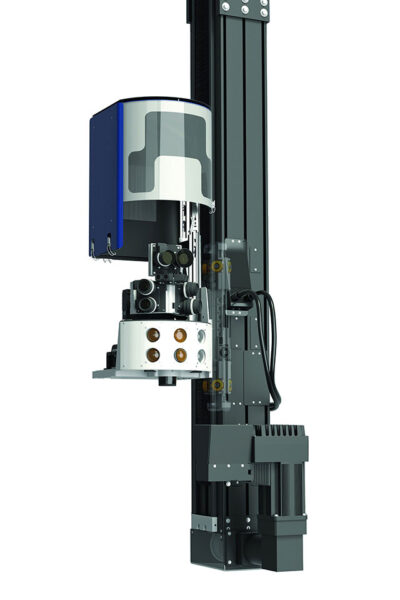

The patented BoxCatcher boosts efficiency in waterside operations. This unique STS crane OCR system features intelligent cameras mounted on vertical rails on the crane legs. These cameras automatically travel to the spreader location, connected to the crane PLC, and capture each container’s information from the optimal position.

BoxCatcher collects essential OCR data and 360° images while seamlessly maintaining crane operations. It does not interfere with the container’s flight path or crane uptime.

Furthermore, with seamless TOS integration, the system instantly transmits data to the terminal operating system (TOS). Thanks to its best-in-class OCR read rates, it minimizes operator exceptions, ensuring smooth operations.

Full STS-crane OCR with just 1 pair of BoxCatcher

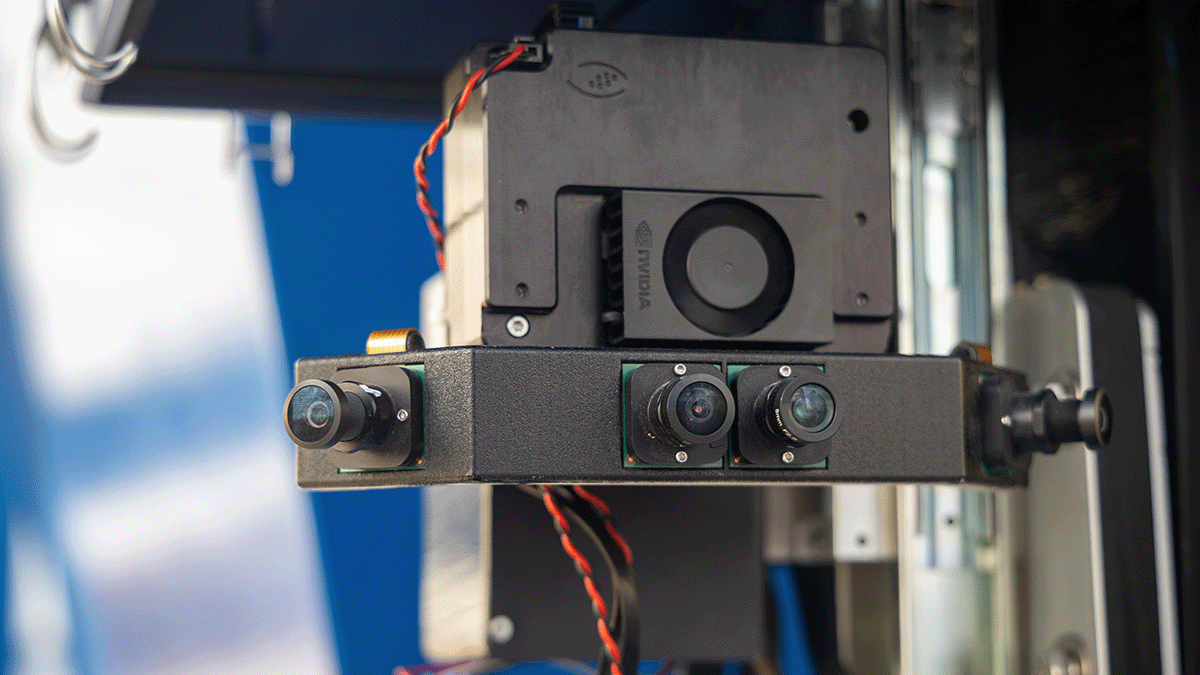

The BoxCatcher Crane OCR/OFR solution uses 12MP global shutter cameras, specifically designed to capture fast-moving objects at speeds of up to 4.5 m/s.

These cameras immediately process images on the internal Nvidia AI processors, generating high-quality data and pictures that seamlessly integrate with the Terminal Operating System (TOS) through the Crane Operating System (COS).

Our dynamic BoxCatcher camera system provides full-crane OCR/OFR capabilities, capturing container ID, ISO code, seal presence, hazardous goods labels, and door direction for both day and night operations. Additionally, it produces high-resolution images processed by the Automatic Damage Inspection AI engines, enabling terminal operators to manage damage claims more effectively.

Camco has equipped more than 300 STS cranes with BoxCatchers across the globe.

Front and back reach operations, all configurations

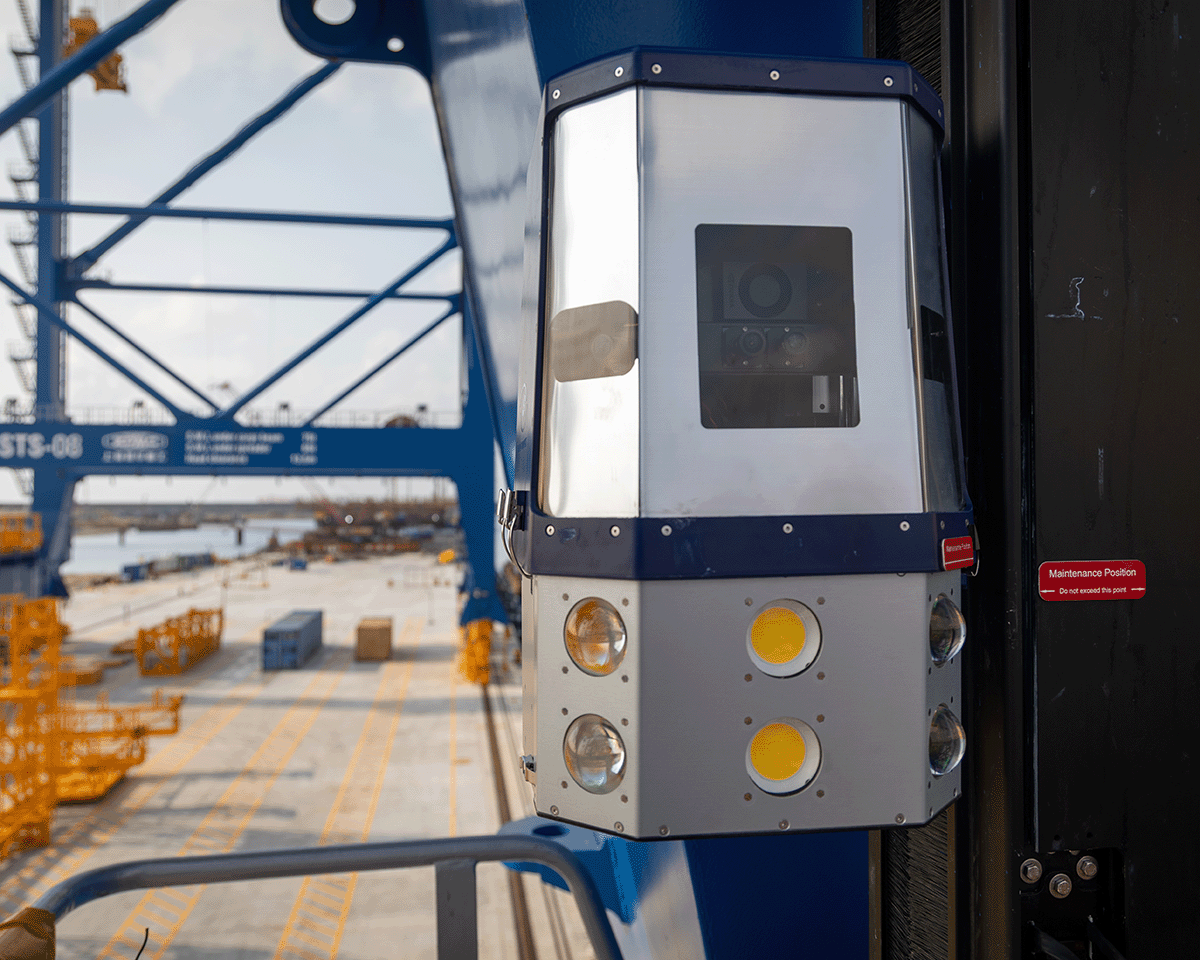

The one-fits-all solution accommodates every possible container configuration, including single, twin, tandem, quad, and 20/40/45ft options. To ensure seamless 24/7 operations in all weather conditions, the cameras feature built-in LED light projectors, providing optimal lighting on demand.

The BoxCatcher autonomously adjusts to compensate for container swing during operations, maintaining accuracy and efficiency throughout.

Patented technology

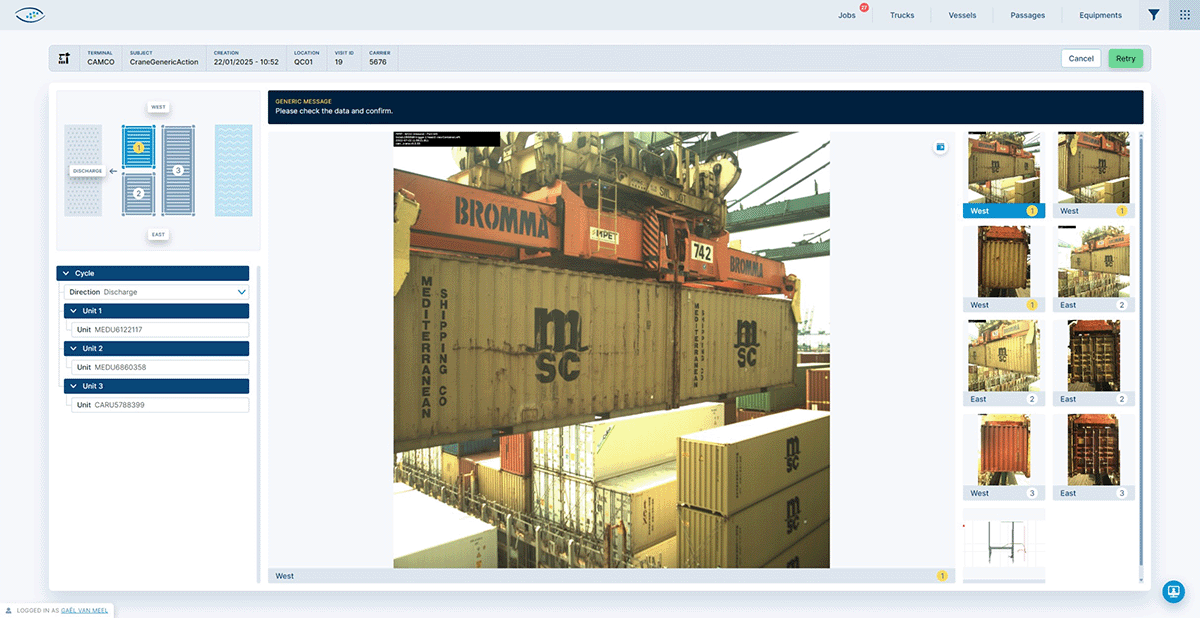

Web-based crane operator application

Crane operators can easily handle exceptions using the Crane Operator Application. This intuitive, web-based tool streamlines OCR correction jobs, allowing operators to validate data directly from high-resolution container images.

Each customer defines specific exceptions, such as incorrect or missing container numbers, seal presence, and hazardous goods labels. With a limited number of exceptions, a single operator can efficiently manage between 6 and 8 cranes, depending on the complexity of the crane operations.

Safe and easy maintenance

Since Camco Technologies’ BoxCatcher cameras are used in harsh maritime environments, preventive service and maintenance are essential.

For easy access, operators can redirect the BoxCatcher camera to its maintenance position.

In service mode, a certified technician can quickly lift the front cover for inspection. Thanks to its modular plug-and-play design, worn components can be replaced within minutes, minimizing downtime.

BoxCatcher Washing Station

To minimize downtime from maintenance interventions, the BoxCatcher can be equipped with an optional Washing Station module. This cleaning device activates automatically when image quality deteriorates, without disrupting the BoxCatcher’s normal operation.

A built-in sensor measures the transparency of the front cover. When image quality declines due to dust, sand, or other debris, the system triggers either a blower to remove dust or water sprinklers to jet water. The remaining droplets are then blown off, ensuring crystal-clear images.

Frequently Asked Questions About the BoxCatcher STS Crane OCR System

BoxCatcher includes smart maintenance features like a repositionable maintenance mode, modular plug-and-play components, and an optional automatic Washing Station. The Washing Station ensures the camera lens stays clean by detecting debris and activating a blower or water jet without halting operations, maintaining optimal image clarity and system uptime.

Operators manage exceptions using the web-based Crane Operator Application. This tool allows them to view high-resolution images and verify or correct OCR data in real-time. With streamlined workflows, one operator can manage 6–8 cranes efficiently, depending on operational complexity.

Yes, BoxCatcher is designed as a one-fits-all solution. It supports every container configuration, including single, twin, tandem, and quad 20ft, 30ft, 40ft, and 45ft containers. It also accommodates front and back reach operations, with built-in adaptive lighting and intelligent swing compensation for optimal image capture in all conditions.

BoxCatcher features patented, rail-mounted dynamic cameras that move automatically with the spreader, capturing container data without obstructing the crane’s path or slowing down operations. It integrates seamlessly with the Terminal Operating System (TOS), minimising the need for operator input and ensuring uninterrupted productivity.

The BoxCatcher system captures full crane OCR/OFR data, including container ID, ISO code, seal presence, IMDG label classification, and container door direction. These details are recorded accurately during loading and unloading, even at high container speeds and under variable lighting or weather conditions.