Key Features

- No limitation in the length of trains

- Supports OCR/OFR of intermodal, non-ISO containers and trailers

- Supports multi-national train types and configurations: single and double stacked

- Supports shunting

- Supports tracking of railcars over multiple rail tracks

- Returns load type, position, and direction per railcar

- Supports European railcar numbers and American & Australian railcar AEI tags

- Seamless interaction and integration with the local TOS or another host system

- Automated Damage Inspection ready

Start processing trains without delay

Camco’s Rail OCR Portal scans complete trains, capturing crucial data without hindering or delaying operations.

Matching rail wagon number and well to container or semi-trailer data, an accurate inventory of the train configuration is available in just a couple of minutes.

With train data instantly available, the processing of the trains can start without delay, improving train turnaround and increasing terminal capacity.

Leading Rail OCR Portal technology

When in- or outbound trains drive through the Camco Rail OCR Portal, line-scan cameras generate high-quality images of each container and trailer on; the left, right and top sides.

Rail wagon and well number, as well as payload, are checked by a dedicated camera.

Optional area scans take images of the container front and back. The following data is retrieved and sent to the Train Gate Operator:

- Container number and ISO code

- Trailer ILU number and yellow plate

- Railcar number, tare weight, and maximum payload

- Container door direction

- Cargo classification

- ADR + IMO dangerous goods labels and UN codes

In addition to OCR/OFR reading, the system supports RFID tag reading for the US and Australian markets as well as train shunting.

All configurations

The Camco Rail OCR Portal is customizable according to required data checks and available footprint.

The Portal supports single and dual-stack trains as well as single and dual-track rails and is also adaptable to overhead power equipment.

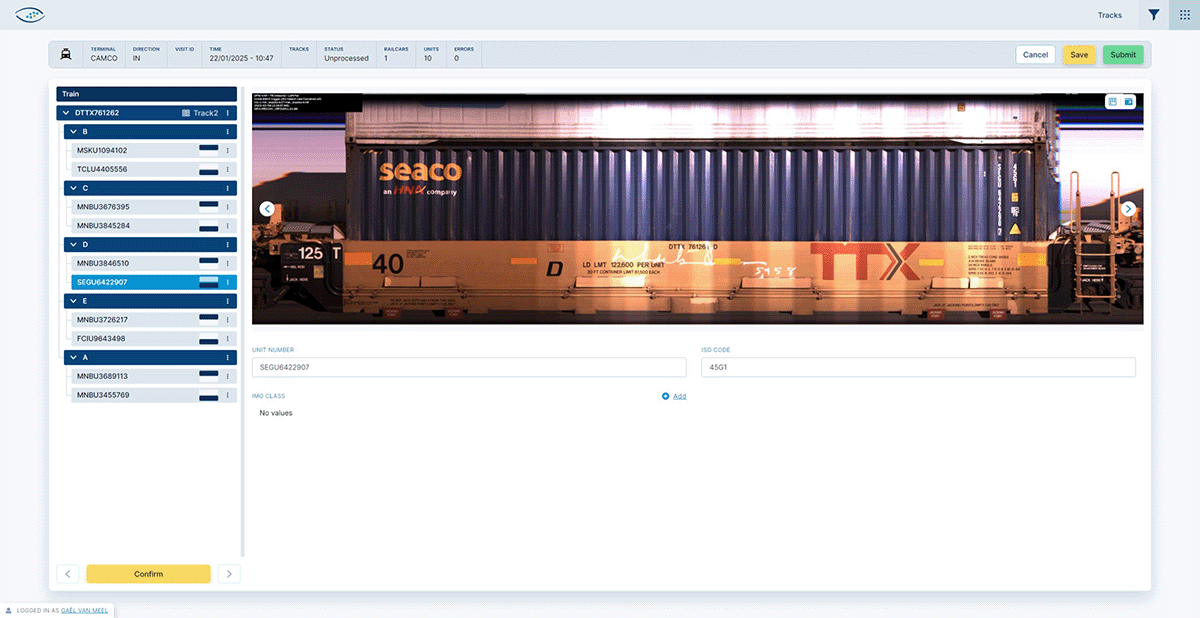

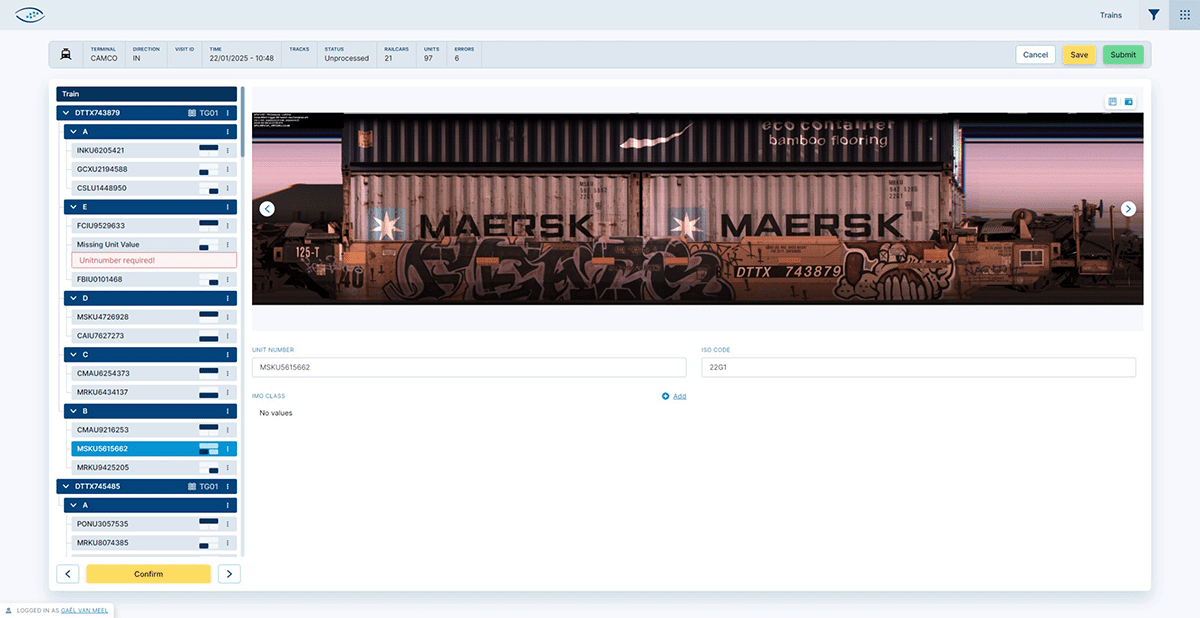

THE BRIDGE exception handling

Before OCR data is sent to the terminal Operating System (TOS), the operator verifies missing data and pictures in the operator tool. The completed data is sent to the TOS. Remote use for multiple sites is perfectly possible and AI-supported damage inspection is available in THE BRIDGE.

THE BRIDGE has two traingate operators. The TrainGate Track Operator for the US market and the TrainGate Passage Operator for the non-US market.

TrainGate Track Operator

In the U.S., operators can view a real-time inventory of the railcars on the shunting tracks using the Track Operator, based on a combination of Camco Rail OCR Portal and RFID technology.

With container RFID tags and tag readers on each shunting track, operators can recompile the exact train configuration. When railcars are removed, the inventory is updated accordingly.

TrainGate Passage Operator

Outside the U.S., trains can be shunted across multiple tracks. However, our software maintains a comprehensive view of the entire train and its full journey, regardless of its physical distribution. It reconstructs the train by integrating wagons from different tracks into a unified representation.

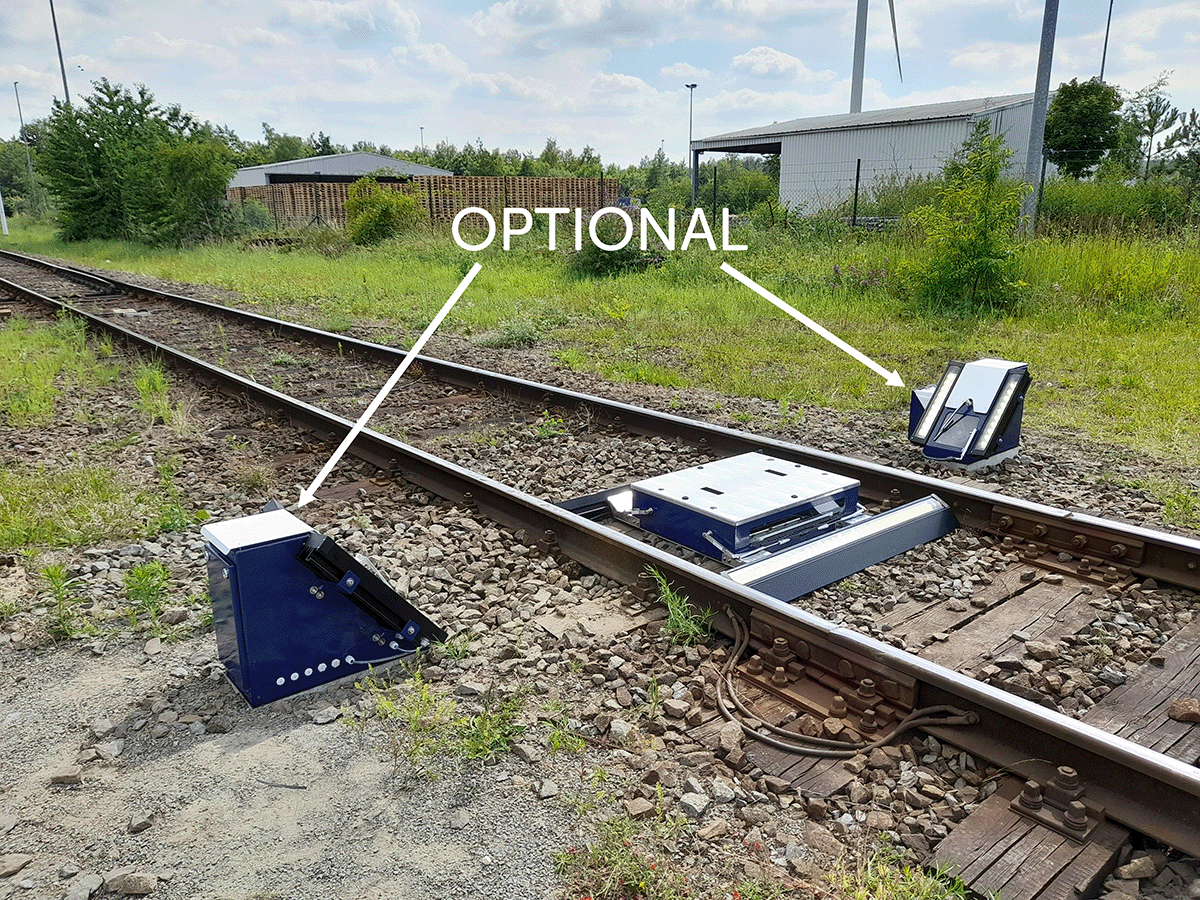

Under Carriage Inspection

Camco Technologies has engineered an advanced solution for scanning and capturing high-resolution images of rail wagon undercarriages. The system includes optional cameras for detailed inspection of wheels and brakes.

The Under Carriage Inspection (UCI) system utilizes cutting-edge camera technology. The high-resolution images of undercarriages it captures are instantly available for remote, fast, and accurate anomaly detection.

Additionally, the optional break scanner identifies worn or missing brake shoes in freight wagons. This data is seamlessly integrated, enabling efficient maintenance and repair management.

Frequently Asked Questions About Camco’s Rail OCR Portal

Exception handling is performed via The BRIDGE platform, which allows operators to verify, correct, and complete OCR data before sending it to the Terminal Operating System. The system includes dedicated interfaces—TrainGate Track Operator for the U.S. and TrainGate Passage Operator for international markets—to support real-time remote monitoring and accurate inventory reconstruction across multiple tracks.

The portal captures data such as container and trailer numbers, ISO codes, railcar ID, tare weight, payload, container door direction, cargo type, and hazardous goods labels (ADR/IMO/UN). It also supports RFID tag reading and undercarriage inspection for advanced maintenance and safety checks.

By instantly capturing and matching container and railcar data, the Rail OCR Portal creates an accurate train inventory within minutes. This enables train processing to start without delay, reducing turnaround time, improving terminal throughput, and avoiding operational bottlenecks.

The system supports a wide range of rail configurations, including single and double-stacked trains, single and dual-track layouts, and intermodal or non-ISO containers. It’s compatible with European railcar numbers and AEI-tagged railcars used in the U.S. and Australia. It also handles train shunting across multiple tracks.

Camco’s Rail OCR Portal automatically scans and identifies railcars, containers, and trailers as trains pass through. It collects crucial operational data such as container ID, railcar number, ISO code, cargo classification, and dangerous goods labels—without interrupting train movement—enabling faster processing and increased terminal efficiency.