COS INTEGRATION

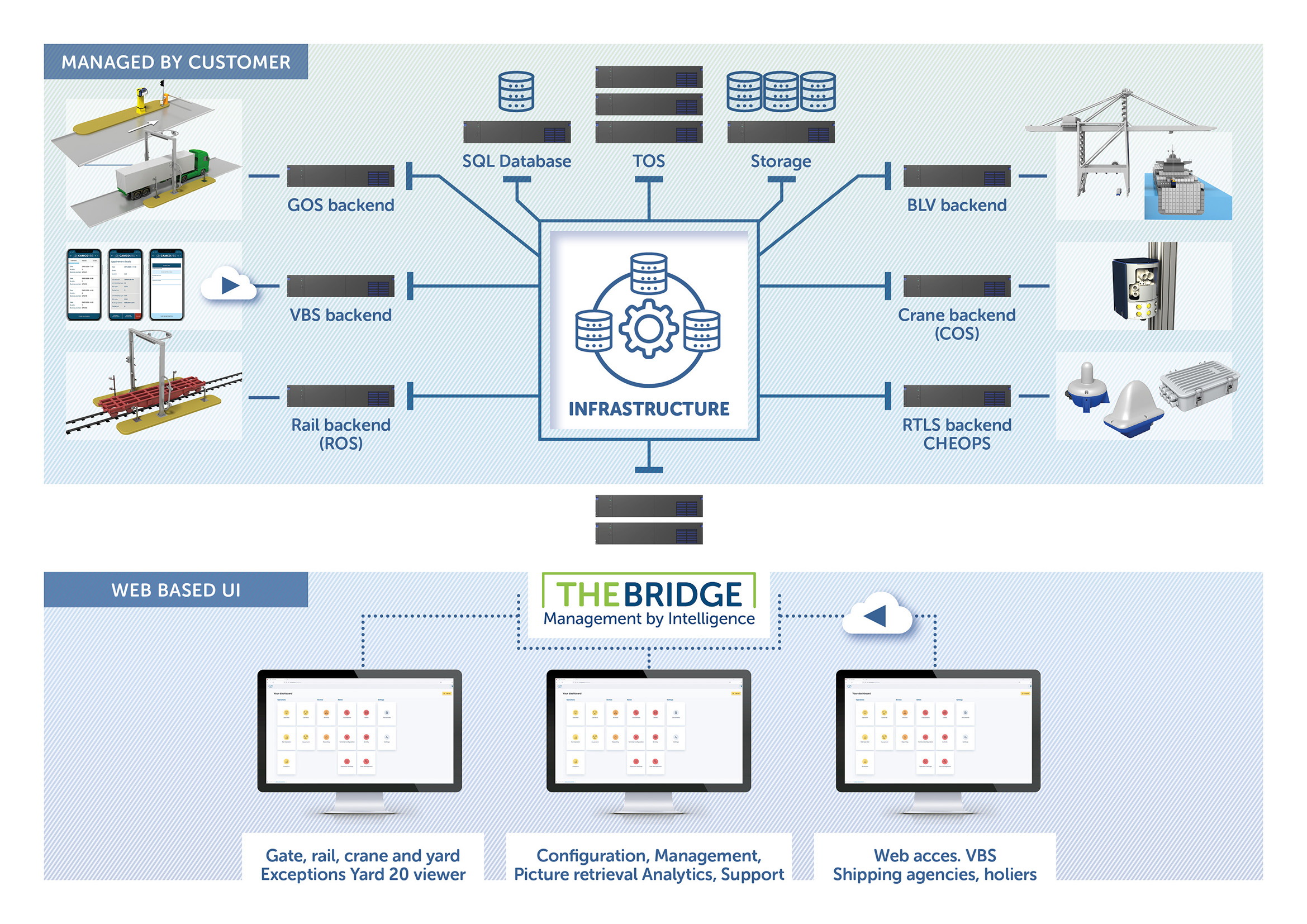

The COS server conencts to multiple systems as the TOS, Storage srevers, SQL database, Crnae OCR controllers and THE BRIDGE.

Container move results and confirmations are sent back to the TOS via COS, while any exceptions or anomalies are forwarded to THE BRIDGE for operational follow-up.

All captured images are securely stored on the image storage server, providing full visual traceability for claims handling, audits, and performance analysis.

CRANE OCR CONTROLLER

At the heart of every crane installation is the Crane OCR Controller—an industrial computer located in the crane e-house. This controller is connected to the camera systems, the crane PLC, and the backend servers in the computer room, where the COS (Crane Operating System) is hosted.

The PLC interface provides real-time operational data such as spreader position, spreader status, and—when available—STS crane location. This data is combined with visual information from the cameras to enable accurate container identification, move verification, and condition monitoring.