Control at the moment it matters

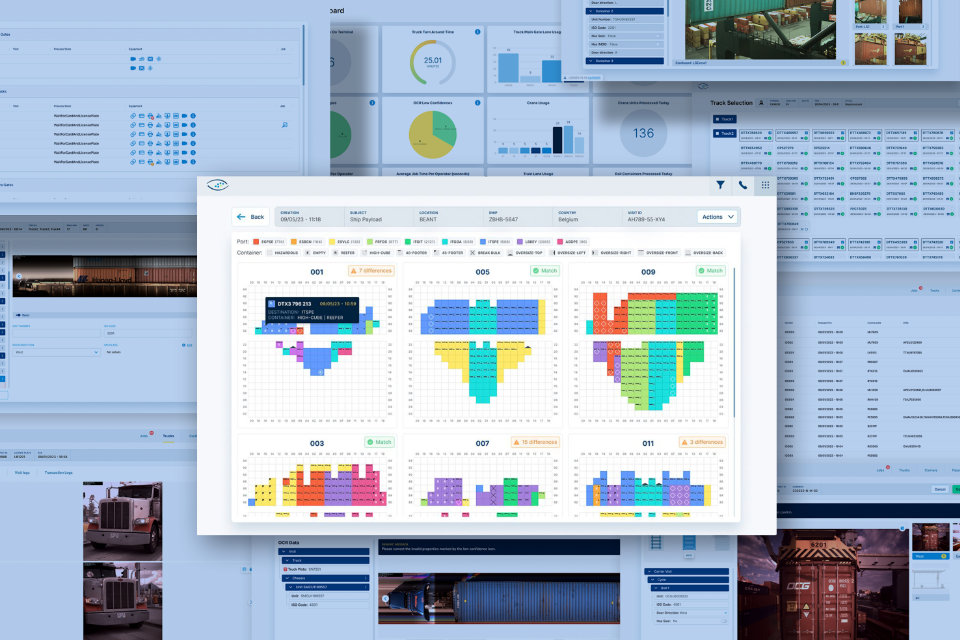

BLV combines OCR container data with STS-PLC positions to confirm the exact pick-up and set-down location of each move.

Any deviation from the loading or discharge plan is detected and processed instantly.

No reconstruction afterward. No surprises later.

Operational impact

What BLV does

- Verifies container ID and bay–row–tier for every yard-to-vessel move

- Automatically updates the BayPlan (BAPLIE)

- Flags critical deviations in real time

- Records container positions with evidential trace

Why this matters

- Prevents mis-stowage and under-stowed containers

- Fewer housekeeping moves in the current and next port

- Safer weight distribution and correct DG handling

- Faster and more transparent invoicing

Less friction. Lower costs.

Unclear stowage leads to time loss on the quay and disputes afterward.

BLV prevents both:

- Fewer corrective moves during discharge

- Less time lost on cut-and-run decisions

- Fewer disputes and claims

- Better predictability between consecutive ports

Seamless integration in existing workflows

BLV runs on top of existing systems:

- Crane OCR (Camco BoxCatcher, 98%+ read accuracy)

- STS-PLC data (spreader position and twistlock status)

- Any Terminal Operating System (TOS)

BLV is a module of our THE BRIDGE platform.

No new procedures. No extra operator.

BLV confirms what is happening — while it is happening.

BLV gives terminals real-time control over vessel loading.

The BayPlan remains correct. Operations continue smoothly. Costs stay under control. More efficient waterside. Less corrective work. Transparent invoicing.