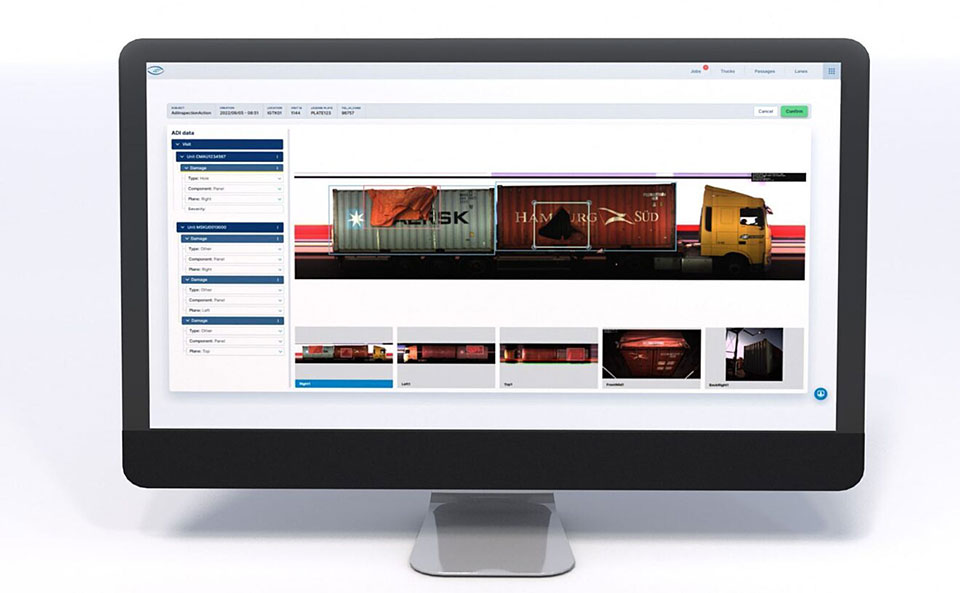

Prevent damaged containers from disrupting operations

Every day, thousands of containers move through terminal gates, quays, and rail tracks. When damaged containers enter the yard, they can trigger accidents, disrupt workflows, and cause costly downtime. Even small issues such as dents, rips, or holes can spoil cargo and erode customer trust. With Argus ADI, terminals can detect and address container damage early, preventing operational risks and safeguarding customer relationships.

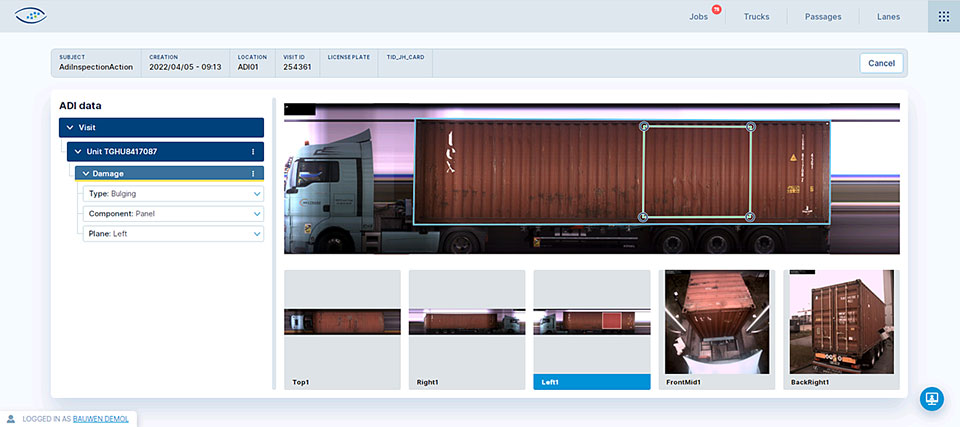

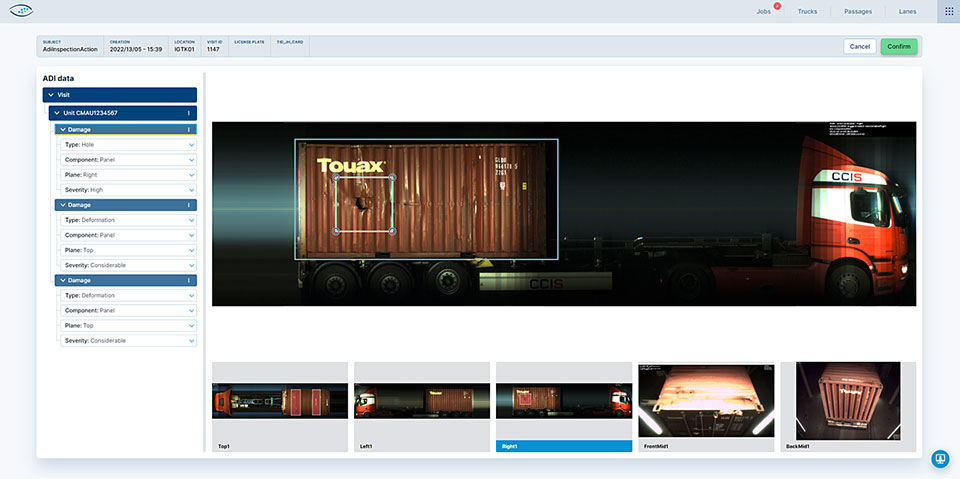

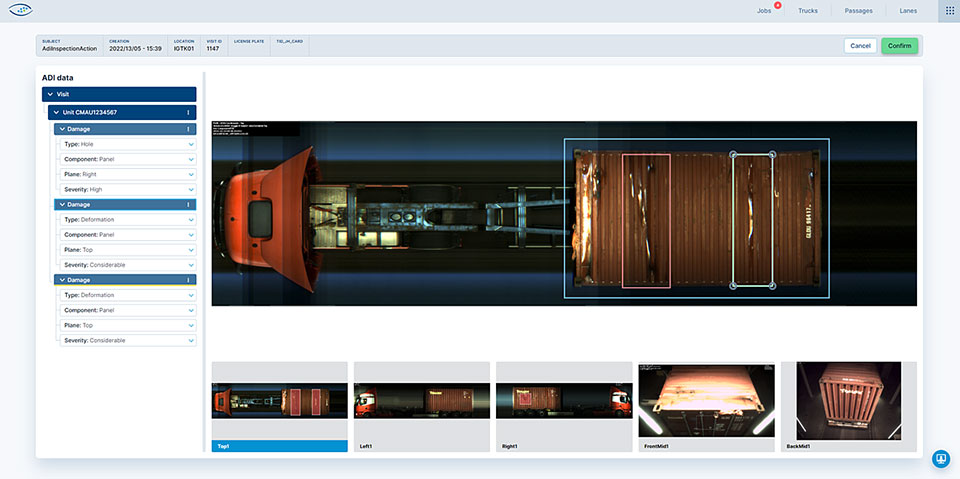

Automated damage flagging

The Argus ADI system automatically scans container images for multiple types of damage.

Focus on critical issues without slowing down the gate

Argus ADI can be configured to match each terminal’s specific priorities. The system automatically flags severe damages for immediate action, while minor issues are stored for later review. Nothing is lost, as every image is archived in The Bridge for detailed inspection and efficient claims handling.

Boosting safety, efficiency, and claims handling

Frequently Asked Questions About Argus Automated Damage Inspection

Argus ADI automates damage detection at entry points like gates and rail terminals, identifying dangerous containers before they disrupt stacking or transport operations. This proactive approach protects workers, preserves cargo integrity, and keeps container flows moving efficiently, without unnecessary inspection delays.

Yes, the system is highly configurable. Terminals can adjust settings to flag only severe damage types, allowing staff to prioritise safety-critical issues while reducing delays. All inspection data is securely stored for future review and damage claim verification, offering both flexibility and accountability.

No, Argus ADI is fully embedded within Camco’s existing gate, crane, and rail OCR camera systems. There’s no need for extra hardware or third-party integration, making it a cost-effective and scalable solution for automated container damage inspection.

By automating the inspection process and flagging only critical damage types, Argus ADI speeds up the gate process without compromising safety. It reduces manual inspections, prevents operational disruptions, and supports faster, more accurate damage claim handling, leading to smoother and more efficient terminal operations.

Argus ADI can identify a wide range of container damage types, including rib deformation, corner post damage, holes, rips, bulging, dents, and issues with doors such as bent bars or broken handles. Detection for tank containers, open-top containers, trailers, and chassis is also being developed to ensure comprehensive inspection coverage.