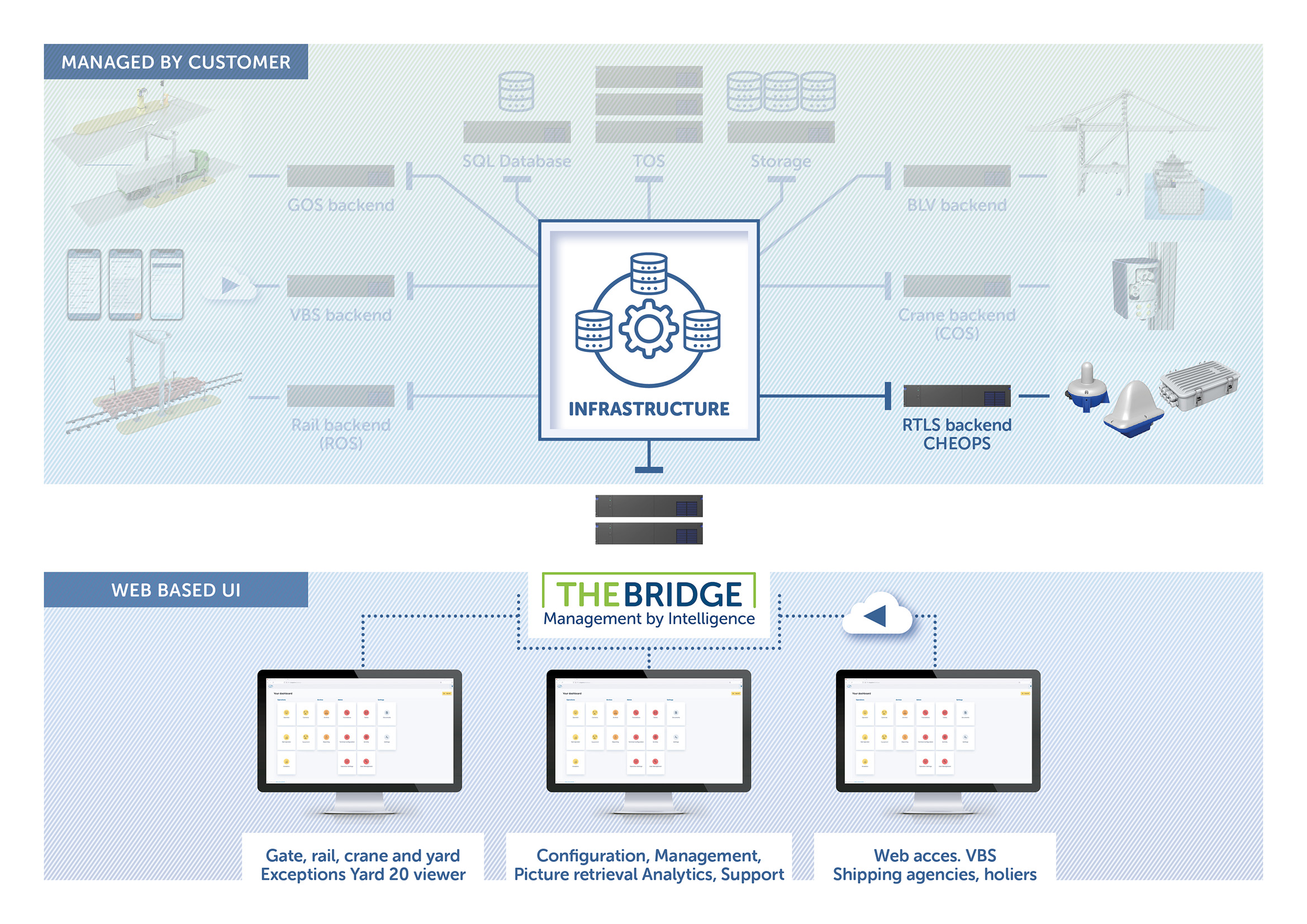

RTLS backend: CHEOPS

CHEOPS powers Camco’s back-end server software, wirelessly connecting with all RTLS devices installed on the CHE’s. It interfaces seamlessly with the TOS, THE BRIDGE (2D maps), and THE TWINBRIDGE (3D maps).

Integration in THE BRIDGE

Camco fully integrates its RTLS solutions into THE BRIDGE.

A 2D terminal map displays all CHE’s in real time, showing ongoing work orders and allowing users to define restricted areas with alarms that trigger when unauthorized CHE’s enter these zones.

THE TWINBRIDGE

The combination of static and dynamic containers, along with IoT-enabled CHE data, has allowed Camco Technologies to develop new automation applications, such as real-time digital twin technology.

This technology creates a visually accurate, interactive digital model of the terminal, containers, and moving equipment. It updates in real-time, reflecting all current activities. As a result, THE TWINBRIDGE helps identify weaknesses, test process changes, and calculate cost savings and performance improvements.

For example, the virtual twin can test methods to speed up loading and unloading, or explore ways to accommodate more vessels.

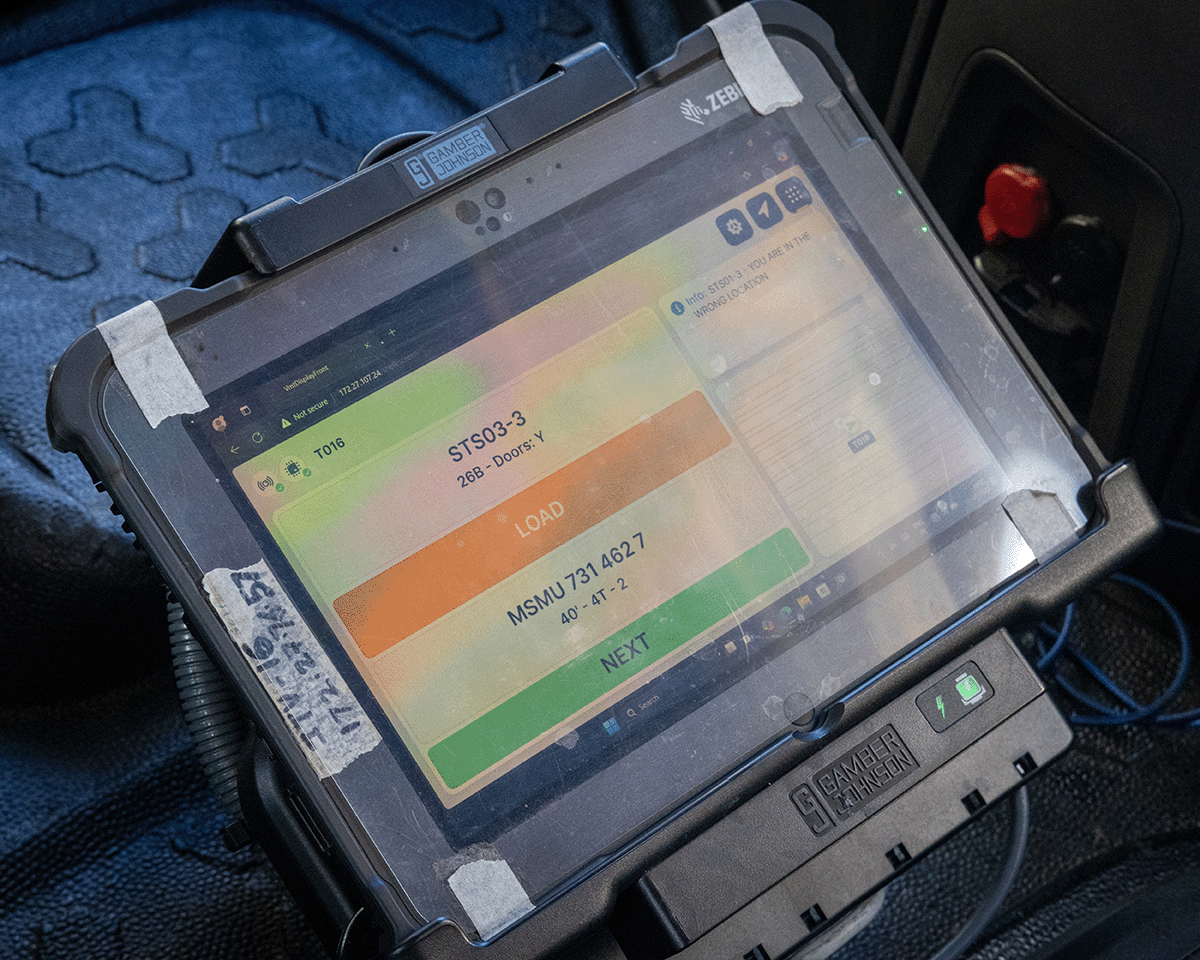

Vehicle Mounted Terminals

Vehicles as straddle carriers, internal trucks, Empty handlers, top handlers, reach stackers all have VMT Vehicle Mounted terminals. Usually, the driver gets instructions from the TOS via this screen. With Camco’s RTLS solution the TOS screen is replaced by an interactive user interface, showing a map and job details.

Frequently Asked Questions About Camco RTLS Products

Due to GNSS limitations under STS cranes, Camco developed a Micro Location Technology (MLT) solution using Ultra-Wideband (UWB) for precise location tracking. UWB anchors on cranes and vehicles provide centimeter-level accuracy in challenging environments.

The TriTech RFID Reader is a high-performance RFID reader used for container yard automation. It combines RFID, radar, and camera technology to extend read range and prevent errors. It’s deployed in OCR portals, gate lanes, yard entries, and on cranes.

Camco’s RT Digital Twin creates a real-time, virtual mirror of the terminal, representing all assets, containers, and operations. It helps identify inefficiencies, test process improvements, and simulate operational changes without disrupting real-world workflows.

CHEOPS is Camco’s RTLS backend server software. It wirelessly connects with all RTLS-enabled devices installed on CHEs and integrates with Camco’s BRIDGE interface (2D maps) and RT Digital Twin (3D maps), ensuring seamless location tracking and process coordination.

RTLS stands for Real-Time Location System. It enables terminals to track containers and Container Handling Equipment (CHE) with high precision across gates, yards, and quay operations. This real-time visibility improves efficiency, safety, and decision-making.