From visibility to foresight

Traditional monitoring provides snapshots. THE TWINBRIDGE delivers a unified, live view of terminal operations—helping operators detect bottlenecks instantly, coordinate activities seamlessly, and plan with confidence. With predictive analysis, terminals can optimize processes, reduce costs, and even unlock new revenue opportunities.

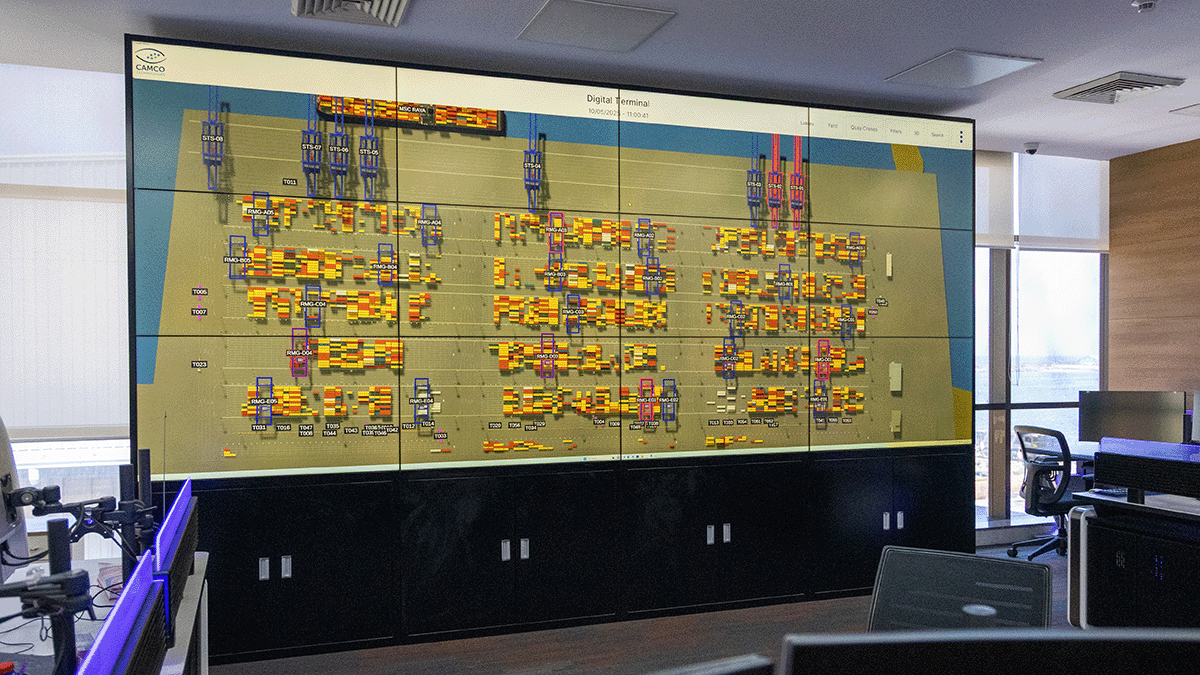

A live digital mirror of your terminal

THE TWINBRIDGE integrates data from every touch point to create an accurate, always-updated model of your operations.

From monitoring to simulation

Beyond visibility, THE TWINBRIDGE enables accurate simulations based on real-time data:

- Test new truck flows, crane setups, or yard layouts virtually

- Anticipate maintenance needs before failures occur

- Reduce operational risks without disrupting real-world activities

By recreating complex scenarios digitally, terminals can make confident optimization decisions that improve turnaround times, reduce energy use, and boost safety.

Smarter operations. Safer terminals. Happier customers.

Frequently Asked Questions About Camco’s Real-Time Digital Twin

Unlike traditional static models, Camco’s RT Digital Twin uses real-time operational data to run high-fidelity simulations. Terminal operators can test alternative configurations—such as changes in crane placement, yard layout, or gate flow—without disrupting live operations, supporting data-driven optimisation and strategic planning.

Yes. With IoT sensor input, the RT Digital Twin detects early signs of equipment degradation, enabling predictive maintenance before faults occur. This reduces equipment failure, prevents downtime, and enhances operator safety by limiting the need for manual inspections in hazardous environments.

The system integrates data from Camco’s camera and RTLS technology, kiosks, vehicle-mounted terminals, and applications like The BRIDGE and VBS. It also incorporates IoT sensor data from terminal equipment, performance metrics from CHE, and external sources such as BAPLIE bay plans and freight forwarder systems to ensure complete situational awareness.

By providing real-time data on container movements, crane activity, yard operations, and equipment status, the RT Digital Twin helps identify inefficiencies, reduce container movement failures, and optimise loading and unloading sequences. This leads to faster truck and vessel turnaround times, reduced energy consumption, and improved throughput.

Camco’s Real-Time Digital Twin is a virtual, live representation of all assets, systems, and processes within a container terminal. It provides a constantly updated digital mirror of operations, allowing operators to monitor, analyse, and simulate terminal performance in real time to support informed decision-making and operational efficiency.