R&D at Camco continues to build on quality and longevity. With the arrival of Filip Forier as R&D manager, Camco Technologies is taking the next step in expanding its development department. The new position follows the strong growth of Camco and the increasing pace at which new products and technologies are being developed.

Filip safeguards the future of R&D and quality, focusing on sustainable, robust, and well-considered development. With an R&D budget equal to 10% of our turnover, he faces a very challenging job.

Experience from the automotive sector

Filip brings extensive experience from the automotive industry, a world where durability and reliability under extreme conditions define the standard. “Deserts, cold, monsoons… Temperatures from -30 to +70 degrees Celsius, combined with seawater and sand—those conditions are far from ideal,” he says. “In the automotive sector, components face the same challenges. That’s why we apply those strict requirements.”

Camco had already been intuitively following many of these principles, but under Filip’s leadership, they are now being structurally embedded in the R&D approach—with clear design rules, internal and external requirements, and a stronger focus on testability and product lifespan. “For many products, we aim for a service life of ten to fifteen years, depending on the type and application.”

For many products, we aim for a service life of ten to fifteen years, depending on the type and application.

— Filip Forier, R&D Manager at Camco Technologies

Smarter testing and validation

Camco is also investing in improved testing infrastructure. With new equipment, prototypes can be exposed to temperature fluctuations and vibrations over extended periods—without needing to travel to the actual deployment environments. But effective testing starts with a solid foundation, Filip emphasizes: “We’re building that with a growing team of highly qualified engineers and a clear focus on high-quality design.”

Sustainable and efficient

Camco is sharpening its focus on sustainability even further, pursuing energy-efficient designs that use less power and lighting, and more compact and lightweight materials. The certification process is also becoming more stringent: every electronic component is certified, meeting all necessary BIS, FCC and CE standards. AI remains a key technology. “Especially in challenging conditions like fog or dust, AI is often the only way to ensure reliable detection,” Filip says.

Control and pride

Finally, Filip is impressed by the fact that Camco develops and manufactures all of its electronics—both hardware and software—in-house. “That gives us full control over the entire process, from concept to finished product. And ultimately, that’s the best guarantee of quality.”

Three examples of how we test reliability

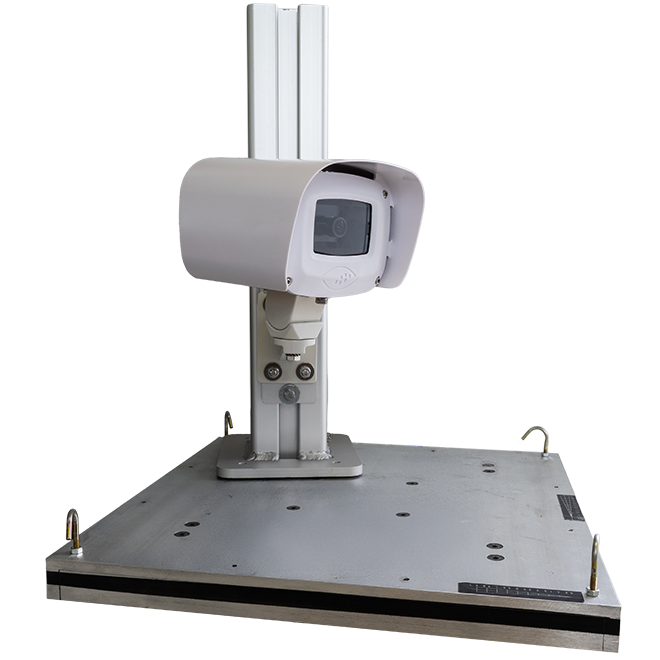

Vibration platform

Heavy port equipment generates constant shock and vibration. To guarantee resilience, our hardware is tested on a dedicated vibration platform that reproduces these forces over extended periods. By identifying weaknesses before deployment, we make sure our products withstand years of daily use in the harshest operational settings.

Climate chamber

Every prototype is subjected to extreme heat, cold, humidity, and salt mist inside our climate chamber. From desert-like conditions of +70 °C to freezing cold at –30 °C, we simulate the full spectrum of environments in which our systems must operate. This ensures that performance and reliability remain stable, whatever the climate.

Software validation

Reliability is not only a matter of hardware. Each software release undergoes rigorous validation and stress testing, covering everything from AI-driven detection algorithms to operator interfaces. We verify stability, speed, and fail-safety under real-life scenarios, so our customers can count on accurate performance day after day.