In container terminal operations, precision is everything. Vessel turnaround times are shrinking, customer expectations are rising, and even small mistakes can have far-reaching consequences. Among the most persistent challenges for terminal operators are those caused by human interaction—errors that quietly disrupt cargo flow, consume resources, reduce efficiency, and create hidden costs.

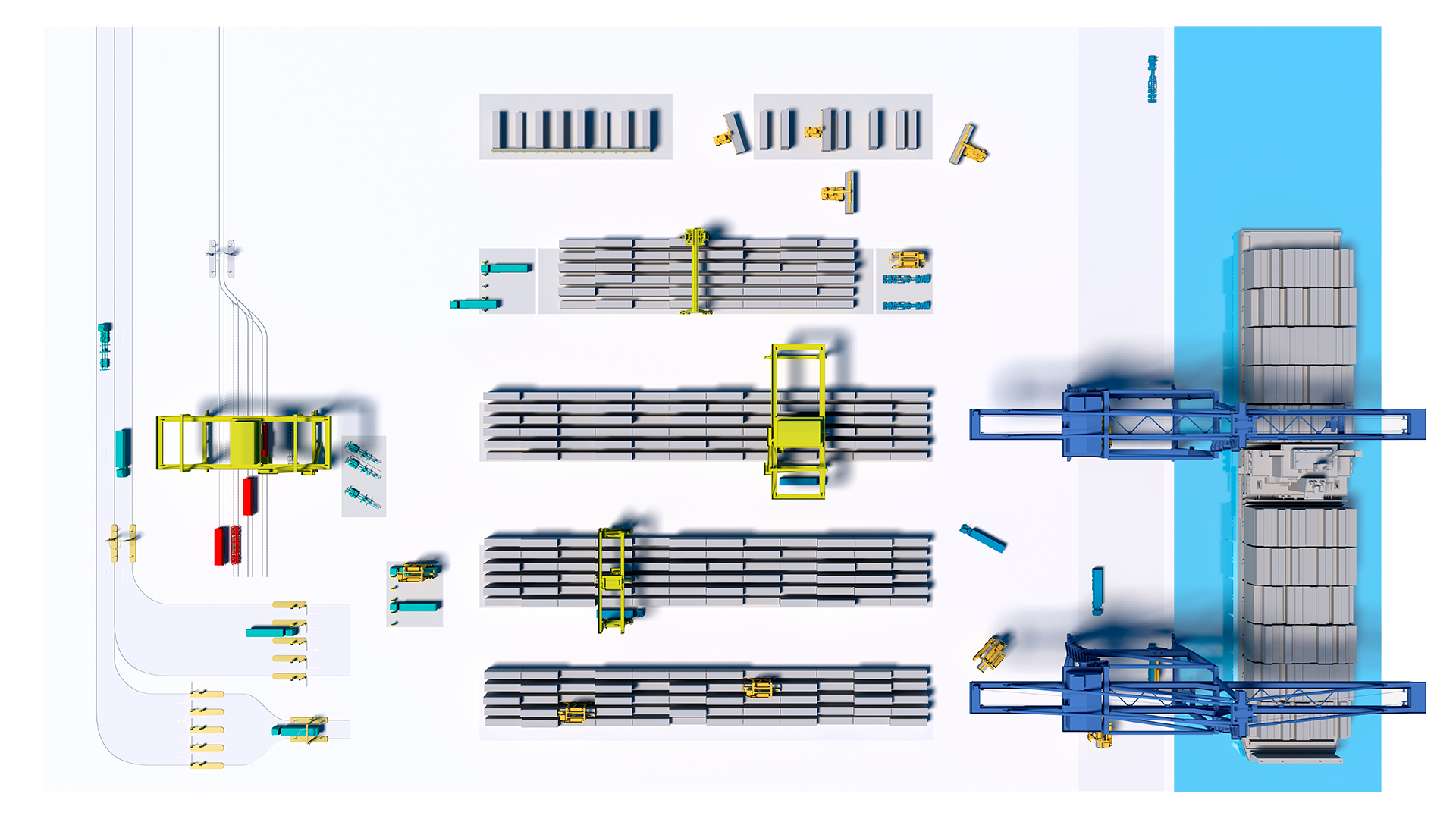

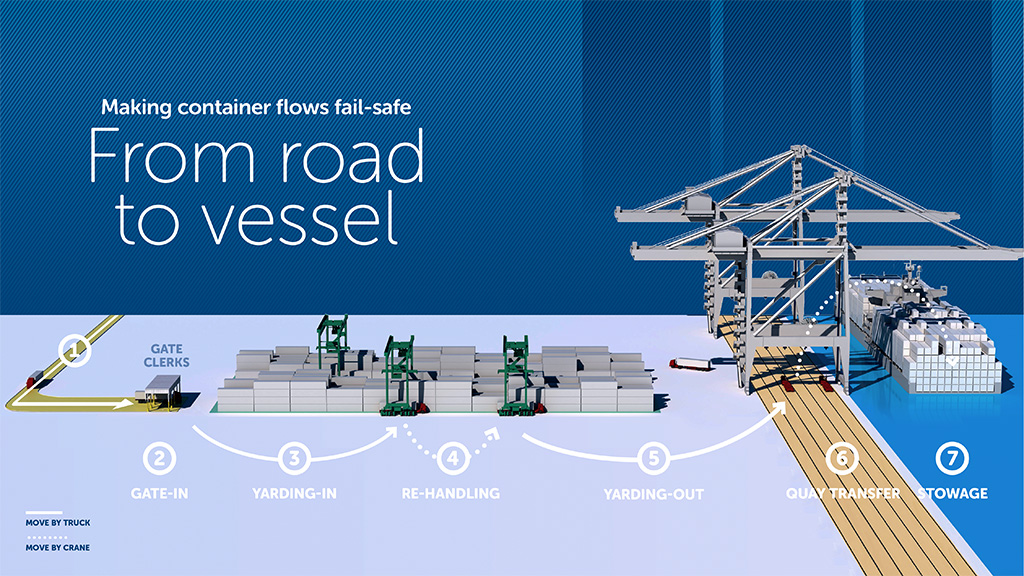

Although terminals invest heavily in Terminal Operating Systems (TOS), many still rely on manual processes for execution and communication. Moreover, even in the most efficient setups, transferring a container from a truck at the gate to a vessel at berth usually requires multiple steps and at least five individual moves.

Each of these steps is orchestrated by the TOS, which dispatches tasks to frontline workers—gate clerks, tallymen, and crane operators. Instructions are usually sent via handheld terminals or two-way radios, with feedback returned in the same way. And that is exactly where the vulnerability lies.

It’s time to rethink how human dependency impacts your operations— and move toward becoming fully traceable, digitally visible, and future-ready—from road to vessel.

The hidden risk of human-dependent TOS operations

The successful execution and accurate feedback of every move in this setup depend entirely on human workers. Furthermore, these individuals often work long, repetitive shifts, frequently in harsh weather conditions. As a result, even the most experienced personnel can succumb to fatigue, distraction, or simple human error.

The result is clear: the TOS becomes effectively blind. It cannot autonomously verify whether its work orders are executed correctly. Consequently, over time, terminals may face significant operational issues, such as unaccounted containers, misplaced units in the yard, or even lost cargo, all without a reliable data trail. As terminals push for greater efficiency, the limitations of human-dependent operations become increasingly apparent. Therefore, addressing this blind spot is critical—not only to improve productivity but also to reduce costly errors and enhance traceability.

The true cost of human error

Mistakes in container handling don’t just delay a single container—they trigger a chain reaction. A wrongly entered container ID, a misplaced stack, or a miscommunication between departments can lead to vessel delays, unnecessary equipment moves, congested yard space, and dissatisfied customers waiting for missing containers. These errors are particularly frustrating because they are entirely preventable—but only by fully digitizing every step of the process, from road to vessel.

Manual checks: small errors, big impact

The two most critical sources of error in terminal operations are container identification and location accuracy. Small mistakes in these areas can escalate quickly. Errors typically occur during manual reading of container or truck numbers and visual verification of pickup and drop-off locations.

Consider a typical container journey from road to vessel. This process involves seven stages. Across these stages, the container or truck ID must be checked four times, and the pickup or drop-off location verified seven times. That’s 11 manual visual checks—and this is a conservative estimate assuming only one re-handling event.

When numbers reveal the risk

In reality, re-handling is often more frequent, which increases both the number of checks and the risk of error. Even with highly attentive staff, every check carries a small chance of error. Assuming an extremely low 0.05% error rate per check (99.95% accuracy), the cumulative failure probability across 11 checks becomes significant.

The probability that all 11 checks are correct is roughly 0.9995¹¹ ≈ 0.9946. That means the probability of at least one error is 1 – 0.9946 ≈ 0.0054, or 0.54%. In other words: more than five out of every 1,000 container moves from road to vessel may encounter a problem purely due to human error during visual verification.

Even with well-trained personnel and low individual error rates, the sheer volume of manual checks across complex container flows introduces unavoidable operational risk.

As terminals seek to increase throughput and reduce errors, automation and AIdriven verification are no longer optional—they are essential. Industry reports and anecdotal data confirm these theoretical calculations.

Digitization as the key to terminal efficiency

Digitizing identification and location verification across gates, yards, rail areas, and cranes represents a major leap in terminal operations. By removing the human factor from critical control points, terminals can deliver digitally verified jobs directly to the TOS—eliminating uncertainty and improving data accuracy.

Each container move can be automatically logged with pictures, GNSS-based location data, and precise timestamps, all stored in a central database. This provides full traceability, supports audits, and enables powerful operational optimizations based on real-world movement data. With a complete digital mirror of the terminal—covering the yard, vessel stowage, and rail cars—the TOS becomes a 100% accurate reflection of the physical environment. In other words: the TOS is no longer blind.

This new level of precision enables smarter planning, real-time decision-making, and immediate detection of anomalies. The benefits go beyond data accuracy. Digitization reduces the need for human clerks at gates and crane operations, lowering operational costs and improving workplace safety by minimizing exposure to high-risk areas.

In addition to automating container and vehicle ID checks, digital systems can take over other routine tasks traditionally handled by clerks, including seal verification, IMDG compliance checks, and automatic damage inspection. By streamlining and accelerating gate, yard, and crane processes, digitization reduces human dependency while boosting efficiency, consistency, and overall terminal performance.